Machines

Axis Linear Floor Drain 12'' xc 3'' Stainless Steel, AXS41A123S

AXS41A123S

Linear Floor Drain 12'' xc 3'' Stainless Steel

₱1,499.00

Deli Inverter MIG/MMA Welding Machine EDL-MIG120-E1

EDL-MIG120-E1

EDL-MIG120-E1

Inverter MIG/MMA Welding Machine

MIG 30-120A MMA 20-120A

₱14,098.00

₱7,049.00

PLATE SHEAR - S2.5Q

S2.5Q

What is a demolition hammer?

The demolition hammer is one of

the power tools specifically designed

for the demolition of the structure.

It is also known as stomping hammers.

Demolition hammer tools are strong

enough to break down various materials

such as wooden walls, concrete surfaces

and tile flooring.

Jackhammers, also known as

demolition hammers or concrete

breakers, are the primary tool

in the breaking of old or non-standard

structures and are a must-have

for construction and renovation

projects that often involve tearing

down concrete slabs, tiles, or brick walls.

A hammer drill, also known as a

percussion drill or impact drill,

is a power tool used chiefly for

drilling in hard materials. It is a

type of rotary drill with an impact

mechanism that generates a

hammering motion.

Hammers are powerful

enough to break up blocks of

brick and concrete with ease.

Our breaker hammers work with

many Cat machines, meaning you

can quickly transform your existing

equipment into a robust demolition

tool just by renting a breaker hammer.

It is perfect for demolition,

trenching, chipping,

breaking

₱13,000.00

₱162,500.00

Ridgid K-3 3-Foot Toilet Auger Snake with Bulb Head

59787

3-Foot Toilet Auger Snake with Bulb Head

₱4,800.00

RIDGID Micro CA-300 Hand-Held Inspection Camera, Borescope,37888

37888

RIDGID Micro CA-300 Hand-Held Inspection Camera, Borescope

₱74,200.00

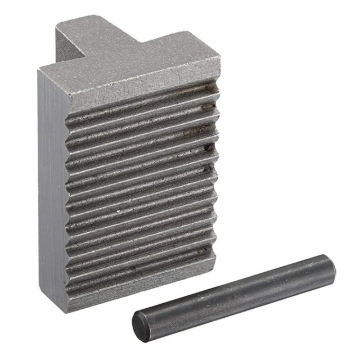

Ridgid Pipe Wrench Parts- Heel Jaw & Pins Assembly , Replacement Pipe Wrench Jaws, Silver, Small, 31560

31560

Ridgid Pipe Wrench Parts- Heel Jaw & Pins Assembly , Replacement Pipe Wrench Jaws, Silver, Small

From ₱1,000.01

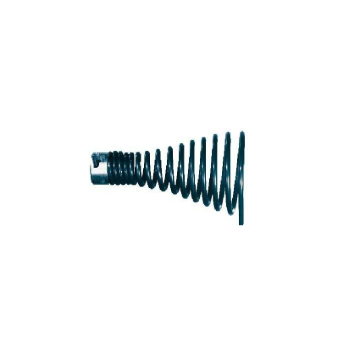

Ridgid Straight Auger For Drain Cleaning Machines, 62840

62840

Ridgid Straight Auger For Drain Cleaning Machines

₱5,500.00

ZEKOKI AIR COOLED DIESEL ENGINE

ZKK178FS-DE , ZKK186F-DE , ZKK186FM-DE , ZKK186FP-DE , ZKK186FPM-DE , ZKK186FS-DE , ZKK186FA-DE , ZKK186FAM-DE , ZKK186FAP-DE , ZKK186FAPM-DE

ZEKOKI AIR COOLED DIESEL ENGINE

MODELS : ZKK178FS-DE , ZKK186F-DE , ZKK186FM-DE , ZKK186FP-DE , ZKK186FPM-DE , ZKK186FS-DE , ZKK186FA-DE , ZKK186FAM-DE , ZKK186FAP-DE , ZKK186FAPM-DE

ALL MODELS ARE : AIR COOLED , 4 STROKE , VERTICAL, SINGLE CYLINDER , DIRECT INJECTION DIESEL ENGINE

From ₱12,201.00

Axis Single Bowl Nano Kit Sink W/ Drainer, AXS1454420SNC

AXS1454420SNC

Single Bowl Nano Kit Sink W/ Drainer

₱4,899.00

Deli Inverter MMA Welding Machine EDL-ZX7-160-E1

EDL-ZX7-160-E1

EDL-ZX7-160-E1 Deli Inverter MMA Welding Machine IGBT Inverter Technology

₱12,738.00

₱6,369.00

INGCO High Pressure Washer, HPWR14008GP

HPWR14008GP

INGCO High Pressure Washer HPWR14008GP

₱5,950.00

PLATE COMPACTOR C90-EY20 YOHINO

C90-EY20

YOHINO PLATE COMPACTOR C90-EY20 YOHINO

POWERED BY ORIGINAL ROBIN ENGINES

MODEL C90-EY20

POWER (HP/RPM) 5/4000

WEIGHT 90 KG

CENTRIFUGAL FORCE (KN) 16

VIBRATING FREQUENCY (VPM) 4750

MAX TRAVEL SPEED MIN. 20-25

PLATE SIZE LXW (MM) 510X450

₱37,000.00

Ridgid 25-Inch x 1 1/4-Inch Flexible Leader, 63090

63090

Ridgid 25-Inch x 1 1/4-Inch Flexible Leader

₱10,800.00

Ridgid Drain Gun/Sink Machine (K-45, K-45-1, K-45AF-7), 49233

49233

Ridgid Drain Gun/Sink Machine (K-45, K-45-1, K-45AF-7)

From ₱62,800.00

Ridgid Funnel Auger For Drain Cleaning Machines, 63105

63105

Ridgid Funnel Auger For Drain Cleaning Machines

₱5,300.00

Ridgid K-6 6-Foot Toilet Auger Snake with Bulb Head

59797

6-Foot Toilet Auger Snake with Bulb Head

₱4,860.00

Ridgid Universal 3ft (Cable) Extension, 31128

31128

Ridgid Universal 3ft (Cable) Extension

₱10,000.00

Zekoki 4 Stroke Air Cooled Gasoline Engine

ZKK550-GE , ZKK700M-GE , ZKK700-GE , ZKK700LS-GE

Overhead Valve (OHV), Horizontal shaft, Single Cylinder with Cast Iron Sleeve, Aluminum Head and Crankcase, Four Stroke Cycle, Air Cooled Gasoline Engine

Lubricant: SAE30 Engine Oil

Mechanical Splash Lubrication

Mechanical Governor

Float Type Carburetor

Recoil Starting System

Ignition System - Transistorized (CDI)

From ₱4,001.00

DIGITAL INSPECTION CAMERA MICRO CA-25-40043

40043

DIGITAL INSPECTION CAMERA MICRO CA-25-40043

₱24,300.00

Ridgid 3/8-Inch x 35-Feet Cable with Male Coupling

62260

3/8-Inch x 35-Feet Cable with Male Coupling

₱16,300.00

Min:

₱0.00

Max:

₱1,887,900.00

₱0

₱1887900